How to use sulfur powder in hose vulcanization

Release time:

2020-04-17

First, the basic concept of hose products

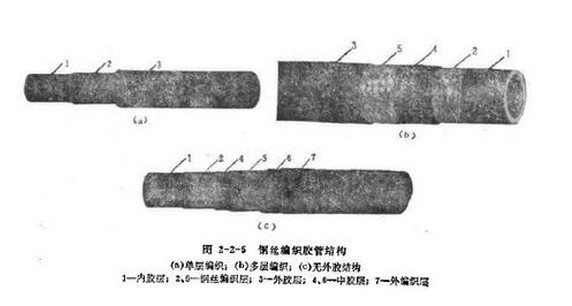

The main structure of the hose is composed of the inner rubber layer, the skeleton layer (fiber textile or metal wire), and the outer rubber layer, while the pure rubber hose has no skeleton layer. Hose is a vital accessory product in rubber products, usually used to transport or pump various gases, liquids, viscous fluids, powdered solids and other materials under positive or negative pressure conditions. And with the continuous development of the hydraulic industry, the hydraulic hose has become an indispensable soft connecting pipe for power transmission in the hydraulic system.

Mainly include: cloth hose, suction hose, braided hose, winding hose, knitted hose, pure rubber hose and other special-purpose hoses.

The structural design of the hose is specifically divided into: the determination of the structure form, the selection of the skeleton material, the determination of the thickness of the rubber material and the rubber layer, the calculation of the working pressure, the safety factor, and the compressive strength. After selecting the corresponding formula design, it is manufactured by processes such as plasticizing, mixing, calendering, extrusion, cutting and molding, and vulcanization. The following mainly explains the vulcanization of the hose.

2. Vulcanization medium and equipment for hose products

Hose vulcanization: mainly under certain temperature and pressure conditions, the plastic tube blank is vulcanized into a hose product with certain physical and mechanical properties and performance.

Depending on the vulcanization method of the hose, there are a variety of vulcanization equipment and media to choose from. Generally speaking, the following vulcanization media are commonly used:

①Saturated steam. It is the most widely used medium in hose vulcanization. Its main advantages are high thermal conductivity, convenient use and low cost. The disadvantage is that the heating temperature is limited by the steam pressure, and it is easy to generate cooling water, resulting in uneven local temperature.

② Overheated water. When vulcanized in water, the setting effect is good, but because the steam is converted into hot water to form a secondary medium transfer, the heat consumption is too large, and the vulcanization efficiency is not good.

③Hot air. The surface of the air vulcanized product has a better surface gloss, and there is no contamination by steam and water stains. It is especially suitable for vulcanized light-colored products; and the temperature and pressure are not interdependent, and the required temperature and pressure can be determined arbitrarily. However, the heat capacity and thermal conductivity are smaller than that of steam, so the vulcanization efficiency is low.

④Other vulcanizing medium. Such as: eutectic metal salts and particulate glass beads, etc.

The most commonly used vulcanization equipment for rubber hoses is a horizontal vulcanization tank, and vulcanization pipes and vulcanization tanks can also be used.

3. Three elements of vulcanization of hose products

Pressure, temperature and time are the basic conditions for the vulcanization of hose products. During the vulcanization process, a certain pressure must be applied, which can increase the compactness of the rubber compound, improve the bonding strength of the rubber layer and the skeleton layer, and help improve the physical and mechanical properties of the rubber hose; the vulcanization temperature and vulcanization time of the rubber compound are mutually restricted. Yes, the vulcanization time varies with the vulcanization temperature, and the "Van't Hoff" law is generally applicable.

When the hose is vulcanized and pressurized, the process of using water-wrapped cloth is often used. Its main feature is that it is not limited by the diameter and length of the hose, and can be wrapped around the outer surface of the hose. The degree of pressure can be controlled manually or mechanically. It is relatively simple, but the disadvantage is that it consumes too much cloth and has obvious cloth marks that affect the appearance; before controlling the vulcanization temperature and vulcanization time, it is necessary to understand the thermal conductivity of the materials used, such as the rubber compound and the skeleton layer, so as to control the parameters and make Hose products achieve better performance.

4. Analysis of the application of industrial sulfur powder in the vulcanization of rubber hoses

①According to the design idea of the hose, the particle size and input amount of the sulfur powder used are selected, and the appropriate process is selected for vulcanization production in combination with the physical properties of the rubber compound and the skeleton layer.

②Similar to rubber products such as tapes and rubber shoes, companies that produce rubber hoses often ignore the quality of sulfur powder itself. In the vulcanization of conventional rubber hose products, sulfur powder that does not meet the requirements of the national standard may also be successfully vulcanized. However, the detection of ash, acidity, iron and other metal ions in sulfur powder is often neglected, which will lead to fatal problems such as poor physical and mechanical properties of rubber hose products, poor pressure resistance and flexural resistance. Therefore, the purchase of sulfur powder must have a strict national standard quality inspection list, otherwise it should not be purchased.

(Statement: The article comes from the Internet and does not represent the views and positions of this site. The copyright belongs to the original author and the original source. If there is any infringement or objection, please contact to correct or delete it.)

Previous article

Previous article

Related News